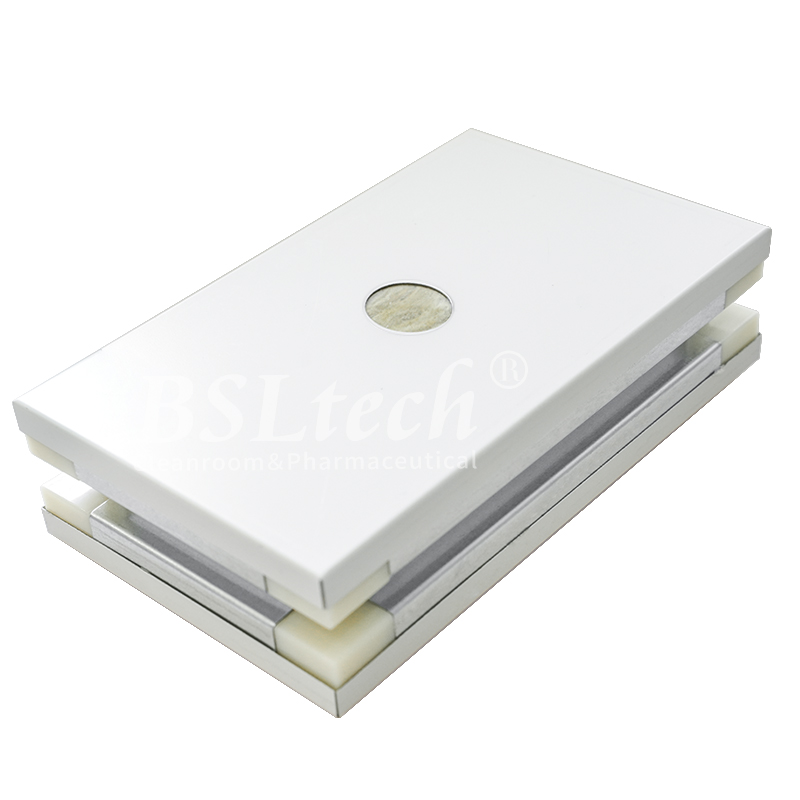

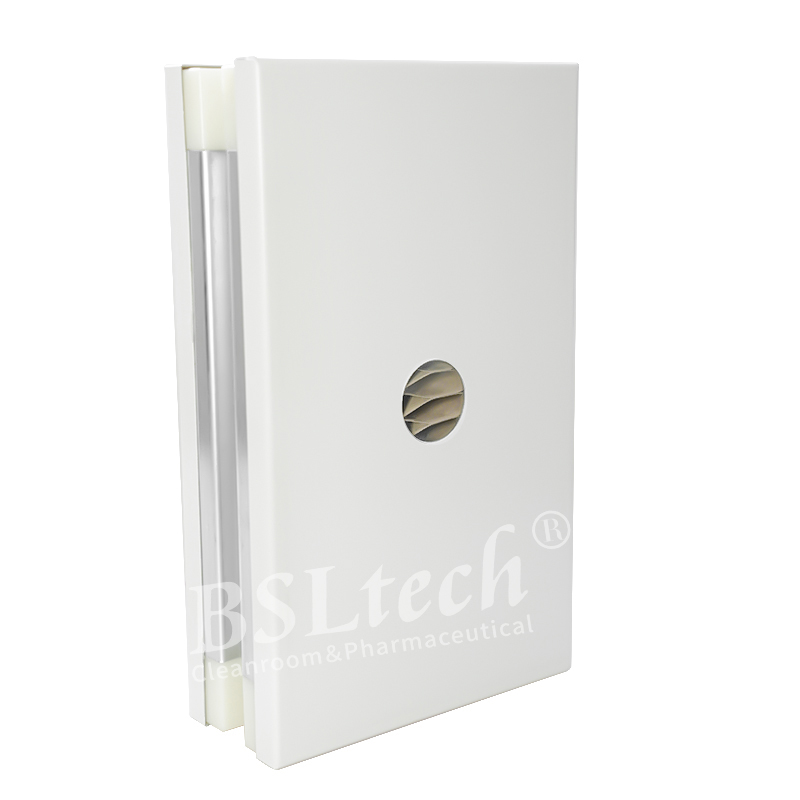

Product Specifications

|

Name: |

50mm Rockwool Panel | 75mm Rockwool Panel |

|

Model: |

BPA-CC-01 | BPB-CC-01 |

|

Description: |

|

|

|

Panel thickness: |

50mm |

75mm |

| standard modules: | 980mm、1180mm non-standard can be customized | 980mm、1180mm non-standard can be customized |

|

Plate material: |

PE polyester, PVDF (fluorocarbon), salinized plate, antistatic |

PE polyester, PVDF (fluorocarbon), salinized plate, antistatic |

|

Plate thickness: |

0.5mm、0.6mm |

0.5mm、0.6mm |

|

Fiber Core Material: |

Rock wool (bulk density 120K) |

Rock wool (bulk density 120K) |

|

connection method : |

Central aluminum connection, male and female socket connection | Central aluminum connection, male and female socket connection |

Rock wool cleanroom panels: the ultimate solution for clean environments

A clean environment is critical to industries such as pharmaceuticals, electronics and food processing. Maintaining the highest level of cleanliness is necessary to ensure product quality and safety. This is where rock wool cleanroom panels come into play, providing the perfect solution for such cleanroom environments.

Rock wool cleanroom panels are specially designed to meet the stringent requirements of clean areas. It is made of high-quality rock wool insulation, which is known for its excellent thermal, acoustic and fire-resistant properties. The excellent thermal insulation provided by these panels ensures energy efficiency, while the sound insulation improves the comfort of the working environment.

One of the main features of rock wool cleanroom panels is their excellent fire performance. Rock wool insulation is non-combustible, ensuring maximum safety in the event of fire. This feature makes it ideal for cleanrooms where the risk of fire needs to be minimized. Additionally, rock wool panels are chemically inert, making them resistant to corrosion and microbial growth. This further ensures the cleanliness and durability of the cleanroom environment.

Another significant advantage of rock wool cleanroom panels is their efficient thermal insulation properties. These panels have excellent heat resistance and help maintain a stable temperature in the clean room. Controlling temperature is critical for industries that handle sensitive products or equipment. The thermal insulation capabilities of rock wool panels help minimize heat transfer, providing a stable and comfortable environment for workers.

Additionally, rock wool cleanroom panels provide excellent sound insulation, creating a peaceful and efficient cleanroom environment. Effectively absorbs sound, reduces noise pollution, and creates a calm working atmosphere. This is especially beneficial for industries where focus and focus are critical.

The versatility of rock wool cleanroom panels makes them suitable for a variety of applications, including cleanrooms, laboratories, operating theaters and pharmaceutical production areas. The panels are easy to install and integrate seamlessly into existing infrastructure. Its modular design provides flexibility and can be customized to meet specific project requirements.

In conclusion, rock wool cleanroom panels are the ultimate solution for clean environments. Its impeccable fire protection, thermal insulation and sound absorption properties make it ideal for industries with high demands on cleanliness and safety. With their versatility and durability, rock wool cleanroom panels ensure the longevity of the cleanroom environment and enhance the overall performance and productivity of the facility. Invest in rock wool cleanroom panels to create a clean, safe and optimal working environment.

Home

Home Products

Products Contact Us

Contact Us News

News