Detail

BSLtech delivers advanced cleanroom solutions tailored to meet the stringent demands of aerospace manufacturing. With cleanrooms ranging from ISO Class 5 to Class 7, BSLtech ensures ultra-clean environments for critical processes like satellite subassembly, electronics assembly, optics handling, and component testing. These cleanrooms provide the precision and contamination control required for high-stakes aerospace production.

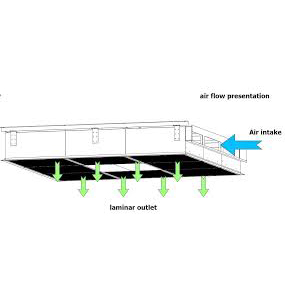

For more critical operations, BSLtech offers ISO 3/4/5 downflow and crossflow cabinets, ideal for precision work in compact spaces. These systems maintain localized ultra-clean zones, helping clients perform delicate tasks such as assembling sensitive electronics and optical components.

Key Features of BSLtech’s Cleanrooms:

Advanced Environmental Control: Equipped with HEPA and ULPA filtration, BSLtech’s cleanrooms maintain strict air quality standards. Additionally, UV-filtered lighting protects sensitive materials, while anti-static (ESD) materials and systems neutralize static charges, ensuring safe handling of aerospace electronics.

Modular and Scalable Solutions: BSLtech cleanrooms are designed to be modular and scalable, allowing for easy expansion and reconfiguration as aerospace projects grow. This flexibility supports long-term production needs without compromising cleanliness standards.

Compliance with ISO 14644, ECSS, and NASA standards guarantees that BSLtech cleanrooms meet international aerospace regulations, providing confidence in quality and precision for all critical aerospace manufacturing processes.

BSLtech’s cleanroom solutions ensure that aerospace companies can carry out precise, contamination-sensitive tasks with the highest reliability, making them an indispensable partner in aerospace production.

Home

Home Products

Products Contact Us

Contact Us News

News