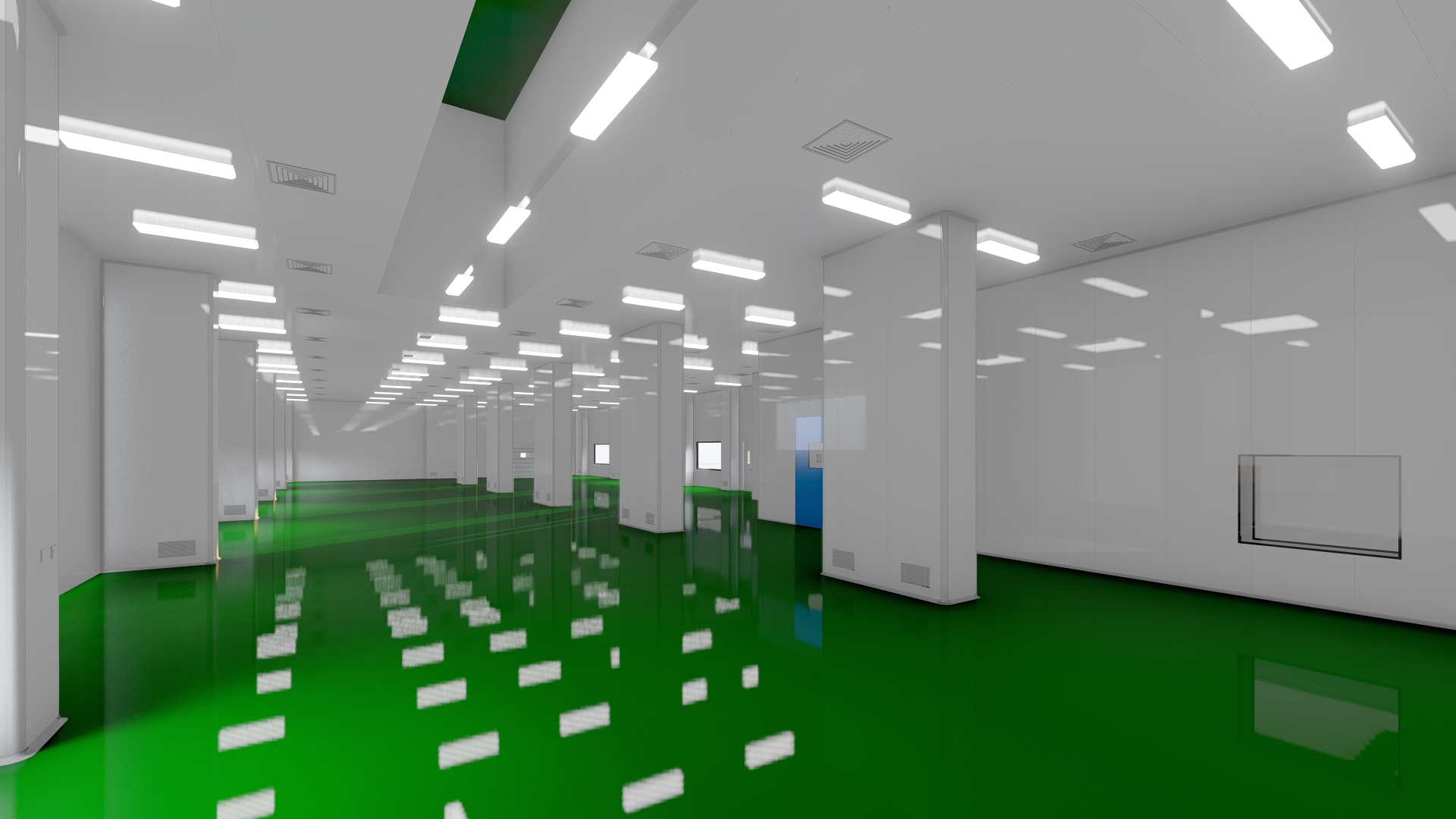

A cleanroom is a controlled environment designed to maintain extremely low levels of particulate matter such as dust, airborne microorganisms, aerosol particles and chemical vapors. These controlled environments are critical to industries such as pharmaceuticals, biotechnology, electronics, and manufacturing, where even the smallest contaminants can have a significant impact on the quality and integrity of the products produced.

Cleanrooms are typically used in industries where air quality is critical and required levels of cleanliness are much higher than those found in normal environments. Cleanroom design and construction are based on strict protocols to ensure the environment meets the required cleaning standards. This includes the use of specialized materials, air filtration systems and strict operating procedures to minimize the introduction, generation and retention of particles within clean rooms.

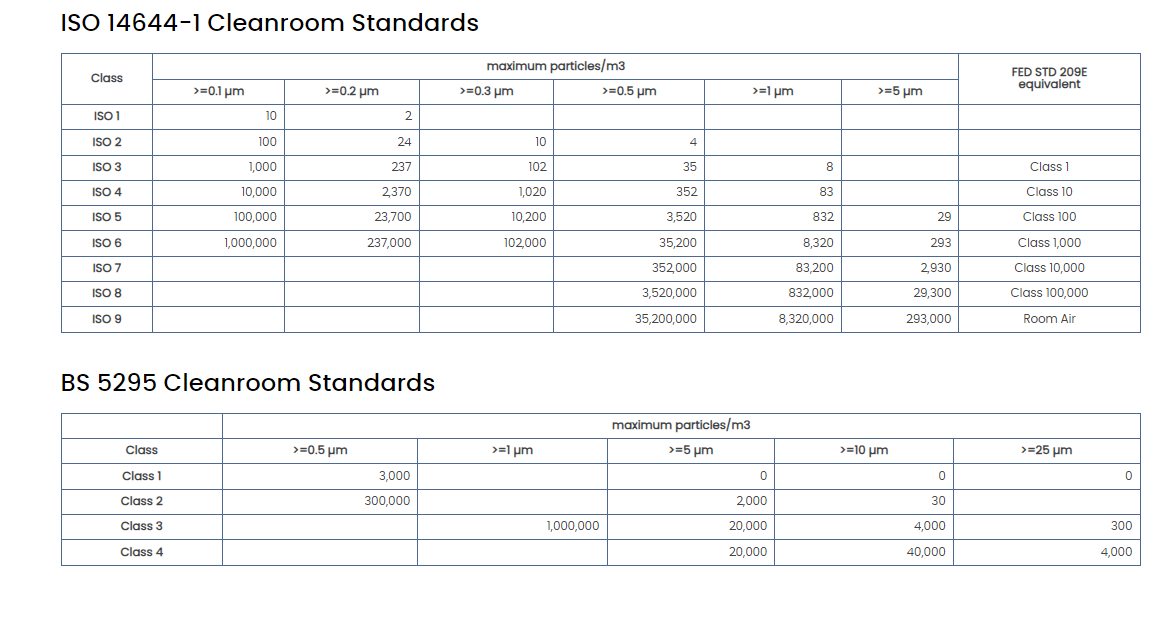

Cleanroom classification is based on the number of particles present per cubic meter of air. This is measured according to ISO standards, with cleanroom classes ranging from ISO 1 to ISO 9, with ISO 1 being the cleanest and ISO 9 the least clean. The classification is based on the size and number of particles allowed per cubic meter of air, with ISO 1 being the most stringent and ISO 9 the least stringent.

Cleanrooms are designed to control a variety of environmental parameters, including airflow, temperature, humidity and pressure. Airflow within a clean room is carefully controlled to ensure contaminants are removed from the environment and clean air is continuously circulated. This is typically accomplished through the use of high-efficiency particulate air (HEPA) filters and laminar airflow systems.

Temperature and humidity control are also critical in cleanroom environments, as certain processes and equipment can be sensitive to fluctuations in these parameters. Maintaining stable temperature and humidity levels helps ensure the consistency and reliability of processes performed in clean rooms.

The pressure differential is used to prevent contaminants from the surrounding area from entering the clean room. Positive pressure is maintained in clean rooms to prevent contaminants from entering, while negative pressure is used in certain areas to confine any potential contaminants to a specific space.

Cleanrooms are also equipped with specialized equipment and furniture designed to minimize particle generation and retention. This includes smooth, non-porous surfaces that are easy to clean, as well as specialized clothing and personal protective equipment for cleanroom workers.

In summary, a cleanroom is a highly controlled environment that is critical to industries where product quality and integrity are critical. Strict cleaning protocols and standards in clean rooms ensure that the environment meets the specifications required to produce sensitive products. By controlling air quality, temperature, humidity, and pressure, cleanrooms provide a controlled environment critical to the production of pharmaceuticals, electronics, and other sensitive products.

Post time: Aug-06-2024

Home

Home Products

Products Contact Us

Contact Us News

News